FC-0205、FC-0208、FN-0205、FN-0208、FX-1000、FX-1005、FX-1008、FL5305、FD-0205

● Applications:

Actuator, industrial automation, medical equipment, office furniture, automobile

● Features:

Actuator components control or drive mechanical systems by converting energy into motion. They are essential in automotive, industrial automation, robotics, and aerospace. Their design and materials directly impact actuator performance and reliability, making them ideal for applications requiring precise motion control.

DESCRIPTION

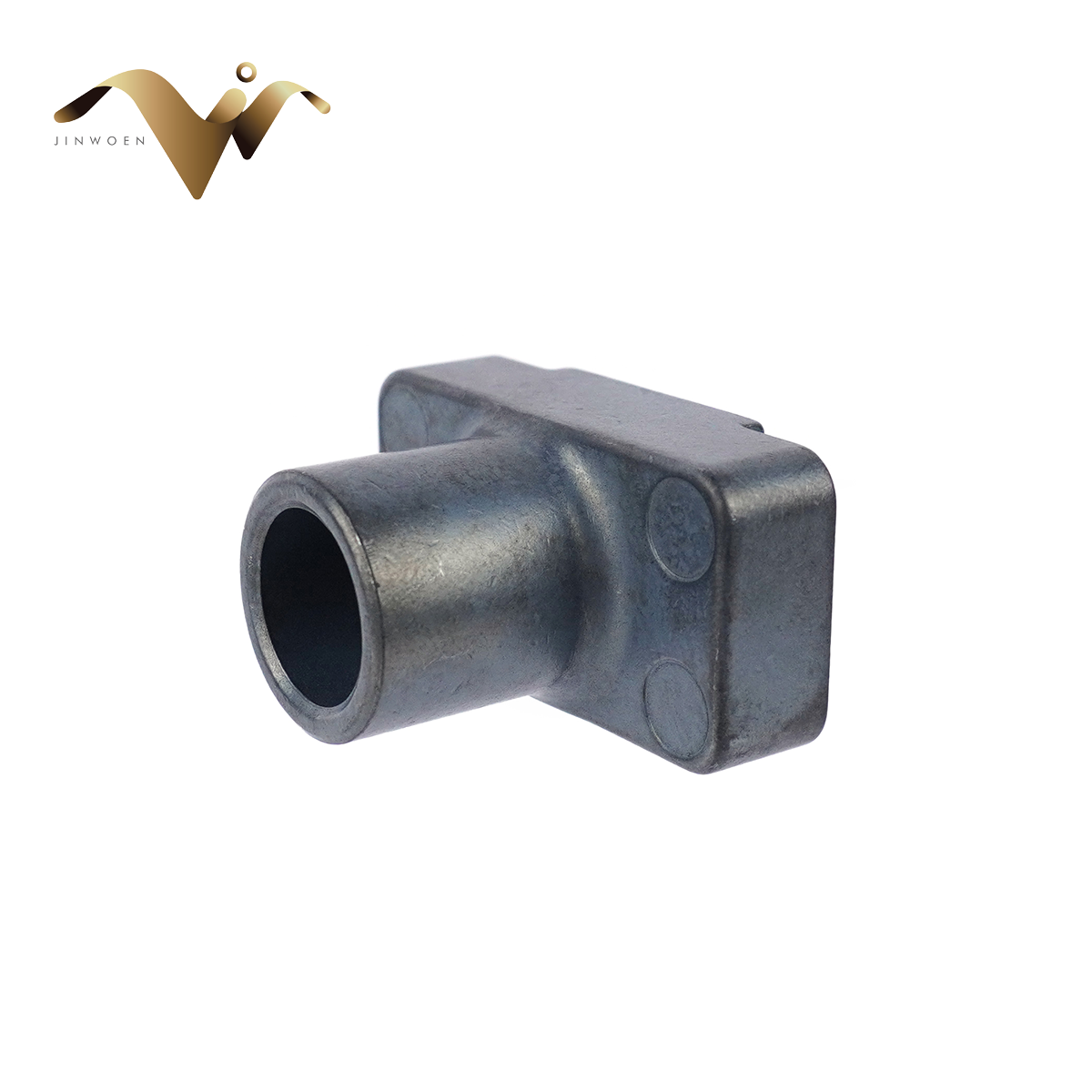

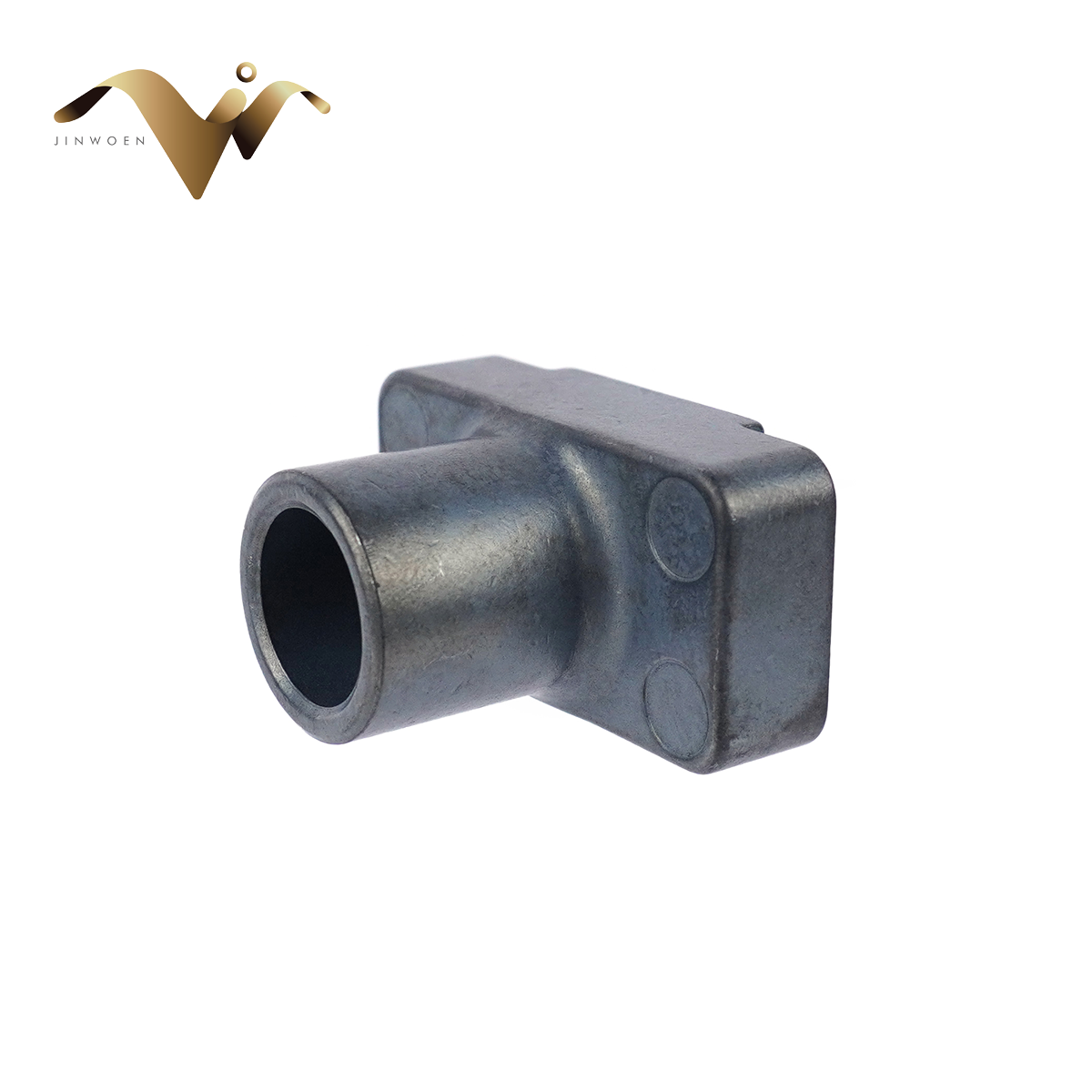

Actuator Parts │ Precision Powder Metallurgy Components Manufacturer from Taiwan

JINWOEN is a leading actuator parts manufacturer in Taiwan, specializing in powder metallurgy motion control components designed for automation, robotics, and industrial systems.

Our actuator components convert electrical or mechanical signals into precise physical motion, delivering stability, accuracy, and reliability across a variety of industries.

Product Overview of Powder Metallurgy Actuator Parts

Actuator parts play a critical role in both mechanical and electronic systems, where they transform control signals into motion to drive movement within machinery or devices.

These components are widely used in automotive, industrial automation, medical equipment, and consumer electronics, helping achieve precise control and enhanced automation.

Manufactured using advanced powder metallurgy technology, our actuator parts feature outstanding wear resistance, corrosion resistance, and mechanical strength.

Even in high-frequency, high-load environments, they maintain long-term stability and consistent performance.

Thanks to the flexibility of powder metallurgy, we can produce components with intricate geometries and tight tolerances, customized to meet the needs of

various applications such as:

precision control valves, linear actuators, steering mechanisms, and transmission systems.

Each part is subject to strict quality testing, ensuring reliability and durability while reducing maintenance costs—making JINWOEN actuator parts an essential element in modern intelligent machinery.

Key Features of Powder Metallurgy Actuator Parts

-

High precision and dimensional stability for smooth motion control

-

Excellent wear and corrosion resistance ensures long operational life

-

Customizable designs for complex geometries and application-specific requirements

-

Reduced material waste through efficient powder metallurgy production

-

Reliable performance under continuous, high-load operation

These features make powder metallurgy actuator parts ideal for industries that require automation, accuracy, and efficiency.

Differences Between Powder Metallurgy Actuator Parts and Conventional Machined Parts

Actuator parts produced via powder metallurgy deliver unique advantages over traditional machining or casting methods:

1. Design Flexibility

-

Allows for the production of complex internal and external geometries.

-

Integrates multiple functions into a single part, reducing assembly steps.

2. Enhanced Material Utilization

-

Near-net-shape forming minimizes material waste.

-

Ideal for mass production with consistent quality.

3. High Strength and Wear Resistance

-

Uniform density and controlled porosity result in superior mechanical stability.

-

Excellent fatigue resistance under repetitive motion.

4. Cost and Efficiency Advantages

-

Shorter production cycles compared with traditional machining.

-

Lower maintenance requirements for end-users.

Applications of Actuator Parts in Various Industries

Actuator components are essential for automation, motion control, and mechanical precision.

They are widely used in industries that demand high performance and reliability, including:

Automotive Industry

-

Steering systems

-

Transmission components

-

Seat adjustment mechanisms

Industrial Automation

-

Linear and rotary actuators

-

Control valves and solenoid assemblies

-

Robotics and conveyor systems

Medical Equipment

-

Micro-actuators for precision instruments

-

Motion control devices for lab automation

Office and Consumer Equipment

-

Adjustable desks and ergonomic furniture

-

Home appliances with automated movement

Aerospace and Machinery

-

Hydraulic and pneumatic actuator systems

-

Positioning and locking mechanisms

With their durability, repeatability, and compact design, JINWOEN actuator parts provide the foundation for high-efficiency motion systems across diverse fields.

Customization Specifications for Powder Metallurgy Actuator Parts

At JINWOEN, we offer fully customizable actuator components tailored to specific functional and dimensional needs.

Material Options

-

FC-0205, FC-0208, FN-0205, FN-0208, FX-1000, FX-1005, FX-1008, FL5305, FD-0205

Shape and Geometry

-

Cylindrical, flanged, or irregular designs suitable for linear and rotary motion systems

Precision Tolerances

-

Ultra-tight tolerances for consistent actuator response and assembly accuracy

Surface Treatments

-

Anti-corrosion coatings and polishing to enhance wear resistance

Performance Parameters

-

Load capacity and motion speed optimized based on application requirements

Production Scalability

-

Flexible for both prototype development and large-scale manufacturing

Each product undergoes comprehensive inspection and material testing to ensure consistent performance in demanding operational environments.

Advantages of JINWOEN Actuator Parts

-

Advanced powder metallurgy production for precision and strength

-

Excellent dimensional consistency and repeatability

-

Customizable for a wide range of actuator applications

-

Reduced maintenance through superior wear resistance

-

ISO 9001-certified quality control and inspection standards

-

Reliable OEM / ODM support for global clients

Custom Actuator Component Solutions & OEM Cooperation

At JINWOEN, we design and manufacture customized powder metallurgy actuator parts that empower intelligent and efficient motion systems.

Our expertise in precision forming, material science, and quality control enables us to deliver reliable solutions for automation, robotics, and industrial applications.

Whether you require miniature actuator components for compact systems or heavy-duty parts for industrial machinery, our engineering team ensures that each product meets your performance standards and application requirements.

Contact us today to learn more or request a custom quotation.

Email: [email protected]