FC-0205、FC-0208、FN-0205、FN-0208、FX-1000、FX-1005、FX-1008

● Applications:

Pneumatic tools, manufacturing, construction, assembly lines, and automotive repair

● Features:

Powder metallurgy pneumatic tool parts offer high precision, strength, and wear resistance, ensuring long-lasting performance in demanding environments. They feature excellent self-lubrication, reducing friction and maintenance needs. With the ability to form complex shapes in a single process, these parts improve efficiency and enhance the durability of pneumatic tools.

DESCRIPTION

Pneumatic tools are commonly used in industries such as manufacturing, construction, assembly lines, and automotive repair. These tools are typically connected to air compressors, using air pressure to drive internal mechanical movements, replacing electricity as the primary energy source. Common types of pneumatic tools include pneumatic screwdrivers, drills, grinders, spray guns, and wrenches. They are often employed in tasks requiring high precision and repetitive operations.

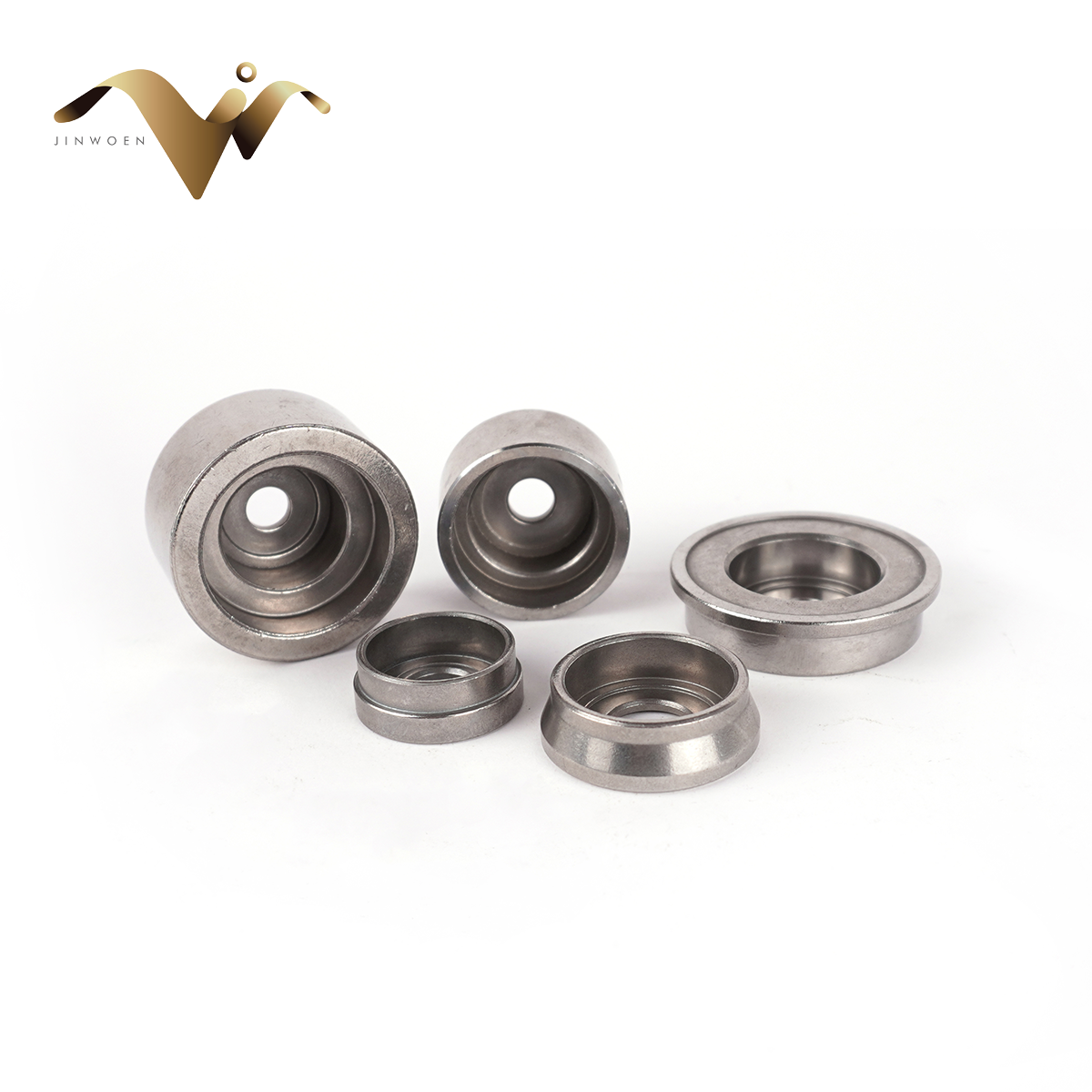

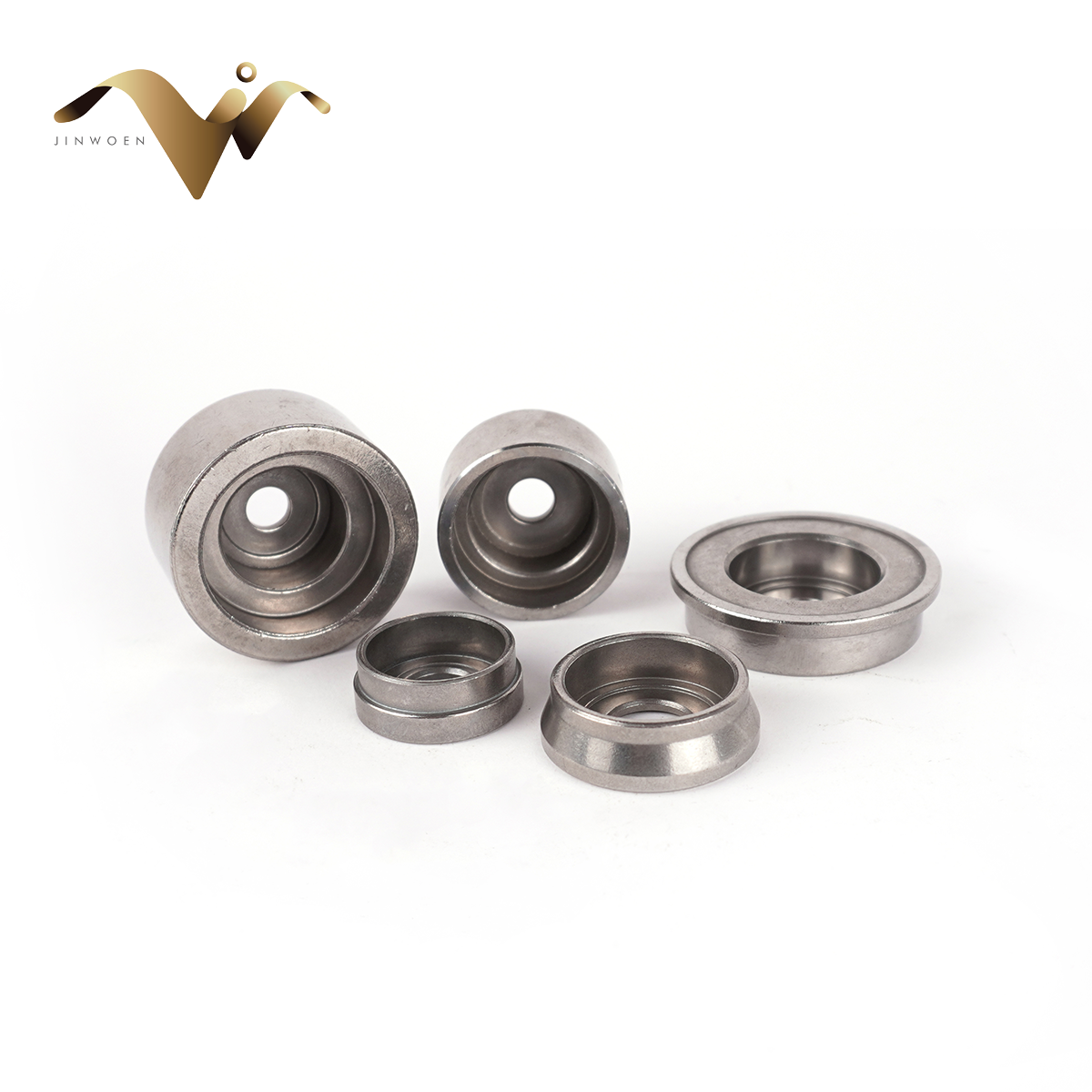

As a trusted supplier of pneumatic tool components, JINWOEN offers a range of precisely designed, high-strength, and wear-resistant cylinders. These components are manufactured using advanced powder metallurgy techniques, ensuring the long-term stability and high performance of pneumatic tools. Powder metallurgy allows for precise control of the density and composition of parts, enabling the production of complex-shaped cylinders to meet diverse tool requirements.

Additionally, cylinders made with powder metallurgy possess excellent self-lubricating properties, reducing friction and wear, thus extending tool lifespan while maintaining stable performance during high-speed operations. Choosing powder metallurgy cylinders not only enhances the durability and performance of pneumatic tools but also increases efficiency and reduces maintenance costs. By choosing JINWOEN ® as your pneumatic tool component supplier, you’re choosing reliability, durability, and a commitment to your success. Contact us today!

● Product Features

Unlock the Future of Pneumatic Tools with our Powder Metallurgy Marvel!

Imagine pneumatic tools with flawless seals, zero gas leakage, and the ability to tackle even the most intricate shapes. Look no further – our powder metallurgy technology makes it possible! Crafted from a range of high-performance materials, including FC-0205, FC-0208, FN-0205, FN-0208, FX-1000, FX-1005, and FX-1008, our components redefine pneumatic tool performance.

Our pneumatic tool parts excel in every way. They're built for high-speed operation, ensuring efficient workflow while keeping noise levels to a minimum. Their exceptional material properties reduce wear and tear, ensuring longevity.

The versatility of powder metallurgy extends to even the most complex shapes, making these components perfect for a wide array of pneumatic tools. Their impressive torque, high density, and precision engineering translate into unmatched strength and performance.

When you choose our powder metallurgy components, you're choosing a future where pneumatic tools redefine industry standards. Say goodbye to leaks, and noise. Embrace the power of precision, strength, and reliability. Elevate your pneumatic tools to new heights with our cutting-edge technology. The future of pneumatic tools is here, and it's powder metallurgy perfection.

● Specification: Customizable

● Materials: FC-0205, FC-0208, FN-0205, FN-0208, FX-1000, FX-1005, FX-1008

● Application: Pneumatic tools, manufacturing, construction, assembly lines, and automotive repair

● Advantages:

1. High torque

2. High density, precision, and strength