- Fabrication of products with intricate shapes and tight tolerances.

- High dimensional accuracy and excellent surface quality.

- Tailored precision production with high efficiency.

- Control over the porosity of formed products.

- Cost-effective, reproducible mass production.

- Finer and denser crystal structure compared to casting.

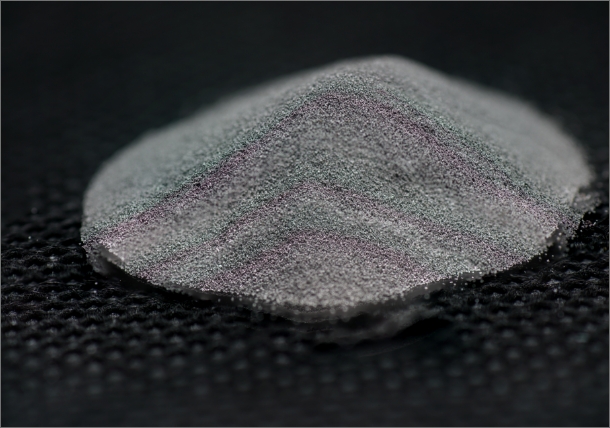

- Material utilization exceeds 97%.

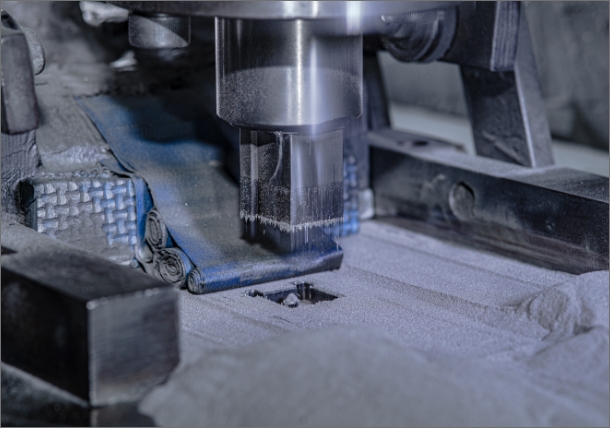

JINWOEN is dedicated to advanced technology and quality products, providing customers with consistently high-quality products and maintaining efficient mass production capabilities. To achieve this goal, we continuously enhance its production technology and possesses a full range of advanced production equipment.

JINWOEN is equipped with powder compacting presses ranging from 8 to 630 tons, accommodating various product requirements and ensuring precision. We also utilize advanced CNC hydraulic compacting machines, sintering furnaces, and other high-performance equipment to ensure the stability and quality of the production process.

-

630 Ton Powder Compacting Press1

-

100 Ton Powder Compacting Press2

-

60 Ton Powder Compacting Press3

-

40 Ton Powder Compacting Press3

-

30 Ton Powder Compacting Press1

-

15 Ton Powder Compacting Press8

-

8 Ton Powder Compacting Press3

-

Conveyor type Sintering Furnace1300℃4

-

80 Ton Sizing Press2

-

40 Ton Sizing Press3

-

30 Ton Sizing Press1

-

25 Ton Sizing Press1

-

15 Ton Sizing Press7

To comprehensively enhance product quality, JINWOEN has established a complete quality assurance system. We understand that the accuracy and reliability of inspection equipment directly affect product quality. Therefore, JINWOEN continually invests in advanced inspection equipment and instruments to manage and track various quality metrics.

Our inspection equipment includes density testers, hardness testers, deflection tester, height gauges, and surface plates. These advanced tools allow us to thoroughly evaluate and ensure product quality, ensuring every product meets customer expectations and standards.

-

Resource Utilization :We employ efficient powder metallurgy techniques to maximize material utilization, reducing waste and raw material consumption.

-

Energy Management :By optimizing production processes and equipment usage, we strive to lower energy consumption and actively adopt renewable energy sources to reduce our carbon footprint.

-

Waste Management :We implement a stringent waste management system to ensure that production waste is properly treated, recycled, and reused.

-

Pollution Control :We take effective measures to control and reduce emissions, ensuring compliance with environmental regulations and standards.

-

Continuous Improvement :We continuously improve our environmental management system through regular audits and employee training, enhancing our environmental performance.

-

Social Responsibility :We actively participate in community environmental initiatives and collaborate with supply chain partners to promote sustainable development.