- Q1.

-

How Do JINWOEN Self-Lubricating Bearings Work?

https://www.powdersmetallurgy.com/Products/2

- Q2.

-

Do Powder Metallurgy Metal Products Rust?

Do powder metallurgy metal products rust? Learn how material selection, surface treatments, and environment optimization improve rust resistance.

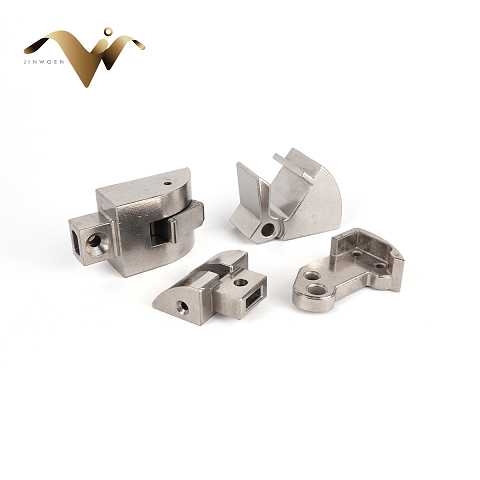

At JINWOEN, we provide more than powder metallurgy. Our expertise covers metal cutting, polishing, treating, rust prevention, grinding, and burnishing, offering a one-stop solution from forming to finishing.

We specialize in custom manufacturing and assembly of automotive and motorcycle components under customer specifications — ensuring precision, performance, and durability in every part we make.

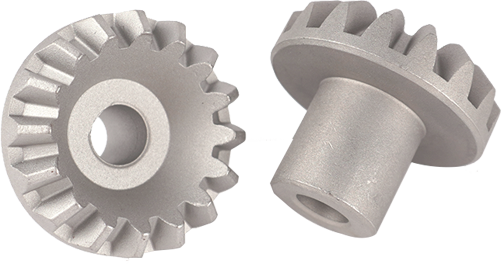

JINWOEN Powder Metallurgy Co., Ltd. was founded in 1987 and specializes in powder metallurgy manufacturing. We excel in producing various precision components such as oil-impregnated bearings, stainless steel, iron-based, and copper-based parts, while also providing metal processing services. Our products are widely used across industries such as automotive, motorcycles, architectural hardware, electric and pneumatic tools, transmission gears, industrial machinery, and healthcare equipment.